Process of Makhana Before it Lands on a Heating Pan

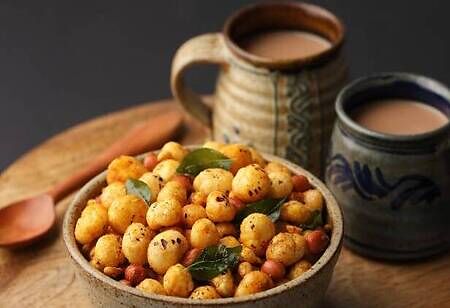

Evening snacks are mostly boiled chickpeas, vada, pakoda, baji, samosa, bread, biscuits, cake among others. Some households serve makhana as a nutritious snack. Loaded with protein, calcium and healthy fat, makhanas not only supply energy, but keep you filled for long durations. The fox-like nuts are grown in the wetlands of Asian countries and go by the name phool makhana (due to their flowery appearance) or lotus seeds. Makhana seeds have various benefits from a healthy snacking to a traditional Chinese medicine.

The global market for fox nuts is expected to reach over 68,443 tons, at a CAGR of 8.5 percent by the end of 2027. The growth behind this is the rising demand for healthy snacking all around the world and makes fox nuts the perfect solution. Here are a few benefits of consuming makhanas.

Cracking Down the Nutrients of Makhana

They reduce binge-eating as they make you feel full and there’s no need to fret about weight gain, as they are low in calories, fat and sodium.

People with high blood-pressures can dig in, thanks to the makhanas’ low sodium and high potassium and magnesium levels.

The high calcium content is good for bones and teeth.

Its low sugar content serves as a good short-interval snack for people with diabetes.

Astringent properties are effective for treating kidney-associated ailments.

Richly bound by fibre, they make for a weight-loss diet intake, as well as, tackle digestion problems like constipation.

They fight against ageing and chronic inflammation and stress with their anti-oxidants.

Other benefits of makhana are preventing hypertension and diabetes for pregnant women, ridding insomnia and coffee addiction.

To become the nutritious snack enjoyed by people, makhana has to undergo a lot of processes, mostly involving muscle.

Manufacturing Process of Makhana

The reason why makhana’s harvesting is a heavy laborious task involving skills is that the seeds have to be harvested from morning around 9:00 am till evening 3:00 or 4:00 pm. Collecting seeds from a field is comparatively easier than from a pond.

After the seeds are collected, they are stored in a horn-shaped equipment, Gaanja. The seeds are cleaned by shaking them in a cylindrical container. The seeds are laid out in a sun bath for a couple of hours to dry and are then packed in small bags. The sun bathing helps evaporate 31 percent of moisture, making them lighter for transporting to the markets and increases the longevity of the seeds. This means, they can be stored for a month but be sure to sprinkle them with water to maintain the freshness. Traditionally, the seeds are preserved in long, cylindrical bamboo sticks that are covered and plastered with cow-dung. The temperature levels are maintained by further covering the bamboo containers with a coarse cloth.

Since each seed has its own unique shape, they are sieved multiple times before grading them. Again, the different sizes of makhana are passed through different sieving machines in rectangular iron plates, called jharna in a few Indian states. This is a lengthy-tedious process that processes different sizes of mahkana through up to 10 different sieving machines. After grading, the seeds are stored safely in different packages. Grading seeds enables consistent heating when roasting them and also increases the efficiency of the processing. The makhana seeds that appear white and plump like circle-shaped pop-corn with red spots are the ones done through lawa grading. The other is a reddish form which is semi-popped and hard in substance is done through thurri grading.

The sun-dried seeds are poured into a cast-iron or earthen pans placed atop a fire and sauted for about five to six minutes at the full temperature of the pan.

For about three days, the seeds are placed in appropriate conditions for tempering to loosen up the hard-seed coats of the kernels.

No sooner are they dried, the makhana seeds are roasted at high temperatures in cast-iron pans, stirred constantly in cast-iron pans. This process increases their lifespans which otherwise have the tendency to rot.

Then they are left for cooling and are manually cleaned. Then at the strike of a wooden hammer, the puffiness of the seeds popped out of the black colour coats. Breaking the seeds’ shells expands into double its size.

The Makhana pops are then used to rub together in bamboo baskets to polish the Makhana seeds. Polishing gives the pop more lustre, more whiteness, and smoothness.

Popped Makhana is packaged using both lined polythene bags and standard gunny bags in a variety of sizes.

Drawbacks

Makhana is physically harvested during the winter by fishermen who dive under the water and extract Guri (Makhana seeds) submerged underwater for lengthy periods of time while exerting themselves.

There is a lot of tedious work involved in harvesting Makhana by hand. Mud gets into the worker's ears, eyes, nose, and mouth as they are collecting Makhana seeds from the ponds. Due to this, the worker also develops skin conditions. Additionally, since the operator is shielded from muck, thorns/prickles, and insects when working inside the pond, there are no injuries or skin-related issues.

The main concerns to processing Makhana are a lack of processing equipment, a high reliance on the climate for drying, and health risks.

From planting through roasting, the entire process needs to be reviewed to identify areas where it may be redesigned to both relieve laborers' suffering and boost output. Makhana seeds are washed, sorted, and dried. Grading is done to maintain uniform heating and pressure during the pop-making process. The procedure is imprecise, unsanitary, and dangerous for the processors.

Processing Makhana seed requires sun drying, which is dependent on the weather. Chronic squatting causes backaches and spine issues, while breathing in smoke from the filthy kitchen causes health issues associated with breathing.

Till date, the entire makhana processing system remains manual because no successful machine has been created. Processing is laborious, time-consuming, and entails a lot of human effort to a significant extent.