Circular Economy for Plastic Packaging

Thimmaiah boasts of an extensive 32 years long career during which he has successfully handled key leadership and managerial positions across numerous companies such as Meritor, Honeywell, Cummins India and Bharath Earth Movers, prior to joining MTL in 2022. In a recent interaction with Bimlesh Prasad (Correspondent, CEO Insights), Thimmaiah shared his insights on plastic packaging growth and urges sustainable practices for recyclability and compliance with regulations. Below are the key extracts from the exclusive interview –

Thimmaiah boasts of an extensive 32 years long career during which he has successfully handled key leadership and managerial positions across numerous companies such as Meritor, Honeywell, Cummins India and Bharath Earth Movers, prior to joining MTL in 2022. In a recent interaction with Bimlesh Prasad (Correspondent, CEO Insights), Thimmaiah shared his insights on plastic packaging growth and urges sustainable practices for recyclability and compliance with regulations. Below are the key extracts from the exclusive interview –

The plastic packaging sector has been witnessing a steady growth in recent year. As per a recent report, the industry has been growing at a rate of 7-9 percent in terms of volume and 10-12 percent in terms of value over the last 5-7 years. Furthermore, this volumetric growth is expected to continue at a rate of 10-12 percent in the coming decade as well. A key factor driving this strong growth of the plastics packaging industry is the increase in disposable income that has resulted in increased expenditure on packaged foods, personal care products, home care products and many others. With the increased competition in the market, new age foods companies are trying to expand their existing categories as well as create new categories like healthy snacking and nutrition led food, which has further boosted the demand for plastic packaging.

Also, today’s consumers are increasingly becoming brand conscious and are hence preferring more organized/branded products. This has led to the companies laying huge emphasis on the packaging of their products in such a way that it can also improve their brand image. Change in lifestyles of today’s Gen-Z population has also been a strong driver for the demand for plastic packaging lately, wherein due to increasing women in workforce, rise in nuclear families and migration of workforce away from their homes has forced the people to increasingly rely on ready-to-eat and packaged foods. With the increased awareness about the environment, a large segment of consumers today opt only for 100 percent sustainable products – ones that are produced using ecofriendly practices, natural raw materials and come with sustainable packaging.

Making Plastic Packaging more Sustainable

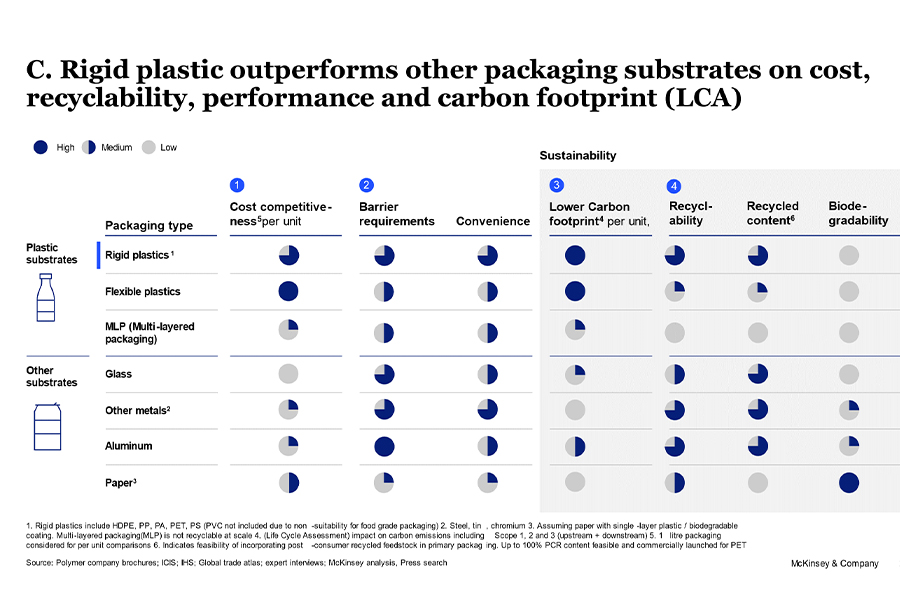

Due to the numerous benefits its offers to the consumers in terms of durability, affordability, aesthetics and being light weight, we are witnessing an increased adoption of plastic packaging in India in recent times. To reduce the ill effects of plastic on the environment, the packaging industry too has invested significantly in R&D to come-up with innovative packaging solutions that are not only ecofriendly, but also offer more advantages than regular plastics. Rigid plastic packaging has thus emerged as the ultimate sustainable packaging solution as it offers the consumers convenience and accessibility, along with being 100 percent recyclable as compared to flexible packaging. Rigid plastics not only have the lowest carbon footprint compared to other alternative packaging materials, but also have the best barrier requirements, low raw material weight per unit, and cost 50-65 percent less. One of the ways of making the current packaging sustainable is by using monomaterial plastic over multi-material/multi-layer packaging. The following diagram gives a calculated perspective on the difference rigid plastic draws from other packaging solutions in terms of cost, recyclability, performance and carbon footprint, according to a data report by McKinsey & Company. Refer to the diagram below.

Continued focus on designing plastics that are recyclable and using recyclable/recycled materials and Post-consumer Resin (PCR) throughout the plastic production process will also go long way in making packaging more sustainable. As many scholars have pointed out, when it comes to the environment, it is not plastic which is a problem but proper disposal of plastic waste. This is because plastic is a very valuable substrate that possesses extremely high calorific value even at the end of life. As a result, we are seeing a change in the behavior towards daily waste disposal – starting from waste segregation to responsible waste disposal practices. As this keep increasing, it will be a win-win from environment, social and economic angle as far as plastic packaging is concerned.

Brand owners and converters must work together to develop supply chain process to collect end-user plastic packaging and bring it back to the converters.

Enhancing Recyclability of Rigid Plastic Packaging

Firstly, plastic manufacturers must ensure 100 percent of the plastic packaging produced are recyclable. Secondly, the use of single layer polymers and Post consumed Recycled plastic wherever possible to maximize the use of recycled material. Also, they should use colors only if necessary, and make sure to use clear and light colors that are NIR detectable. Since labels serve as an important part of packaging, organizations must ensure that the label is easily separable from the packaging, and labels must be designed of compatible polymer for easy recycling. Additionally, accessories such as caps, closures and dispensers must not only be produced using mono-material and minimal color but should also be designed to ensure maximum compatibility for recycling. Further, manufacturers must restrict the use of inks, additives & fillers with heavy metals and direct printing will have a great impact on enhancing the recyclability of products.

The Indian government has already put in place Plastic Waste Management rules 2016, with a clear mandate on EPR (extended producer responsibility) which requires all brands, importers and manufacturers to use min 30 percent of post-consumer recycled plastic in their plastic packaging, and over a five-year period, this goes up to 70-80 percent. This is expected to provide a huge fillip to the circularity of plastics in India and significantly reduce plastic waste in the environment. Additionally, we believe effective collection process, stakeholder participation, and educational content on proper disposal of plastic waste will be important to ensure recycling ecosystem thrives in India. A few other effective ways to make plastic packaging solutions more sustainable are continuous `innovation in light-weighting of packaging, use of post-consumer recycled plastic in bottle-to-bottle applications, and incorporating monomaterial packaging.

To summarize, brand owners should incorporate sustainable packaging as a part of brand story, encouraging consumers to prefer sustainable packaging brands. This will invariably be increasing the adoption of recycled plastic packaging, moving away from multilayer & flexible packaging to rigid packaging. Additionally, brand owners and converters must work together to develop supply chain process to collect end-user plastic packaging and bring it back to the converters.